There’s hardly a wire and cable manufacturer without a turn-around capstan being used in their facility. Using an outer wrap belt to apply tension on the cable and inner capstan “liner” belt to protect the cable from the metal capstan sheave, it’s an integral part of the wire and cable production process.

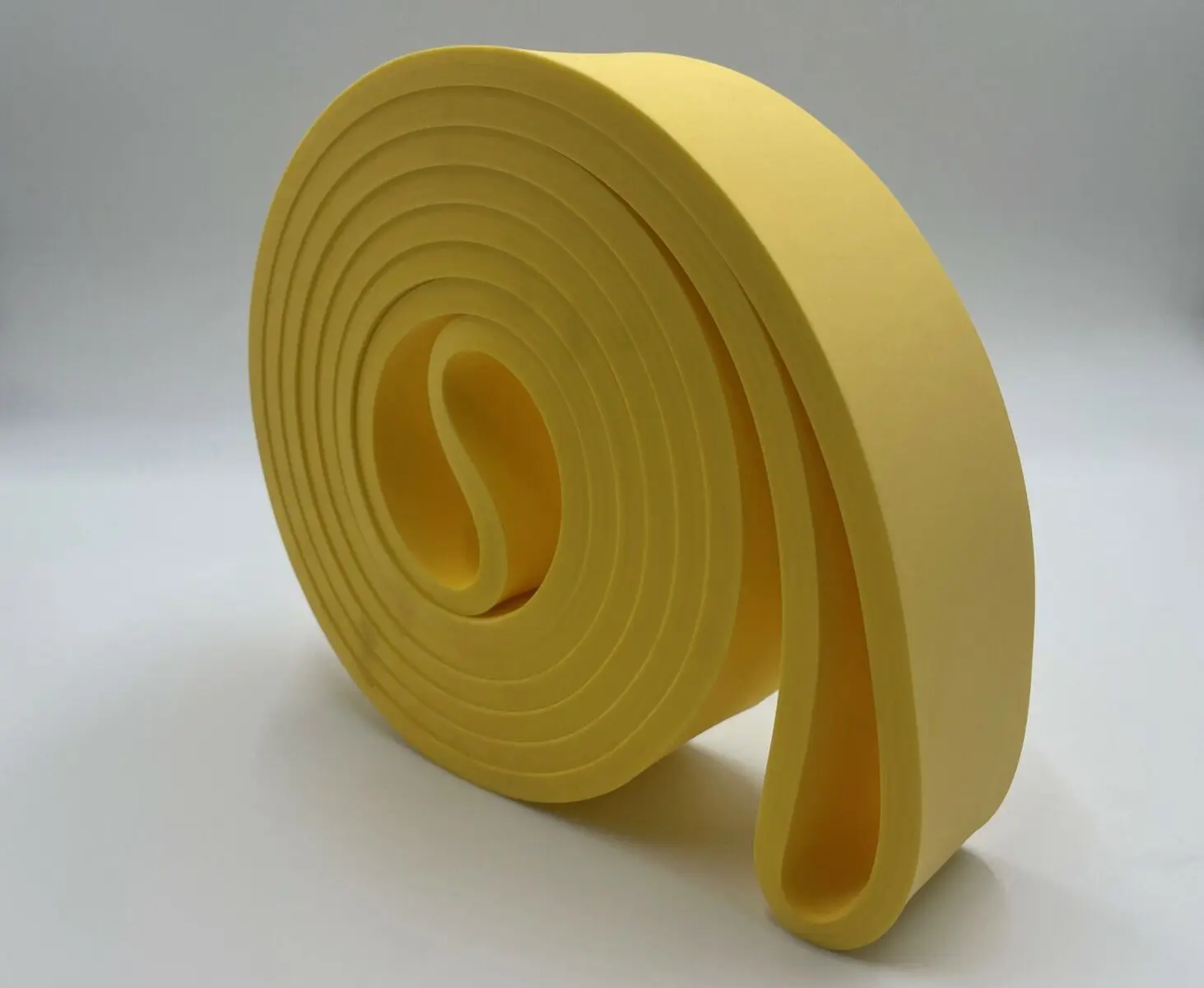

For years, there has been one offered solution for the inner capstan liner belt. A spliced “rubber band” that can be stretched onto the capstan sheave. These belts are time-tested but offer no mechanical advantages and can sometimes be trouble points in the wire manufacturing process. Rainbow Rubber & Plastics, Inc. has developed a truly endless liner belt made of elastic urethane that offers greater wear and abrasion resistance. Removing the splice area also removes the risk of failure of the splice. Working closely with manufacturing partners, we were able to generate a 60% reduction in the consumption of capstan belting for their process across all machines.

What are Polyurethane Liners

Urethane liners are an elastic-based component used to protect the belt from the metal sheave. Urethane liners differ from other commonly used liners due to their higher abrasion resistance and significant elastic memory. This makes them a perfect solution for load conveyance and power transmission applications.

In the past, a spliced “rubber band” was the go-to solution for belt-based equipment within the wire and cable industry. This offered no mechanical advantages and was known to create points of contention during the wire manufacturing process.

Advantages of Polyurethane Liners

Unlike solutions of the past, urethane belts and liners yield prominent advantages for the wire and cable industry. The key benefits of urethane liners include the following:

Abrasion Resistance

One of the key advantages of urethane liners and urethane belts is their abrasion resistance. Urethane liners are durable and are less prone to developing grooving and cutting during their use. This heightened amount of resistance makes the belt or lining last much longer than other solutions.

Easy to Install

When it comes to urethane, installation is easy. This unique elasticity allows for easy replacement and the creation of different shapes—all due to its thermoplastic makeup.

The combination of its ease of installation and other advantages make the use of urethane belting and liners a beneficial investment for a variety of facilities within the wire and cable industry.

Maximize Efficiency with Polyurethane Liners

Various industries thrive on efficiency and effectively avoiding equipment downtimes. Wear and abrasion issues with equipment make finding the right solution all the more important. Maximize the efficiency of your operations with Rainbow Rubber & Plastics.

Our commitment to creativity and innovation has allowed Rainbow Rubber & Plastics to develop the liner belt. This urethane belt offers greater wear and abrasion resistance and elastic memory. Our team has worked with manufacturing partners to generate a 60% reduction in the consumption of capstan belting for their process across all machines.

The key features of the revolutionary Capstan Liner from Rainbow Rubber & Plastics include:

-

- No Splice, No Seam. The splice area is removed, eliminating the risk of splice failure.

- Enhanced Performance. Our advanced urethane liners offer better control and higher speeds.

- Longer Lifespan. Our solution provides superior durability and reduced maintenance requirements.

Specifications:

-

- PU ground surface

- 50 and 70 duro ShA

- Thickness: .313” (other thickness available)

- Color: Yellow

- Unreinforced elastic

- Temp Range: 50ºF to 140ºF

Here is how belts from Rainbow Rubber & Plastics compare to other solutions:

| OEM Belt | Rainbow Solution | |

|---|---|---|

| Life | 5-weeks | 12 to 13 weeks |

| Usage | 200 belts and 200 liners per year | 80 belts and 80 liners per year |

| Machine Down-Time | Intermittent for belt failures and liner splitting | Scheduled for routine maintenance on a 90-day cycle |

| Annual Costs | $72,000 plus unexpected downtime cost | $36,000 |

Other reasons the wire and cable industry should favor Rainbow Rubber & Plastics’ Capstan liner include:

-

- Ease of Installation. A simplified setup process for overall convenience and efficiency.

- Superior Control. Precise and reliable performance.

- Increased Speed. Operational efficiency sees a boost of efficiency and quickness.

Looking to maximize the efficiency of your operation within the wire and cable industry? Turn to Rainbow Rubber & Plastics for the largest inventory of Caterpuller & Capstan Belts in North America.

Rainbow Rubber & Plastics has spent over five decades working side-by-side with operators on the plant floor to develop a leading understanding of unique manufacturing challenges. The wire and cable industry is ever-evolving, driving the importance of partnering with a trusted provider for the long haul. Rainbow Rubber & Plastics is the answer to that solution.

Comments are closed.